REDUCING OPERATING COSTS

When it comes to managing costs, choosing the right lubricants makes all the difference. We offer our customers a team, specialized in energy and environmental technologies to identify the most suitable products for each use, reducing the quantities of lubricant needed besides prolonging the lifetime of machinery and tools. We extend the lubrication intervals and rationalize the number of products in use leading to storage optimization. Furthermore, our high-performance lubricants lead to a significant decrease in energy and fuel consumption.

GUARANTEEING RELIABILITY AND PERFORMANCE

Our customers want reliability and maximum longevity for their machines and systems, avoiding unexpected repairs and downtime issues. This is why we offer customers our laboratory services to ensure, through regular analysis, maximum reliability of the lubricants in use. The analysis of the lubricant allows us to assess its performance, the degree of pollution by external agents, both solid and liquid, as well as the presence of wear resulting from malfunction or impending failure. With predictive maintenance, it is possible to monitor the efficiency of the machine fleet while maintaining high standards of safety and productivity throughout the process.

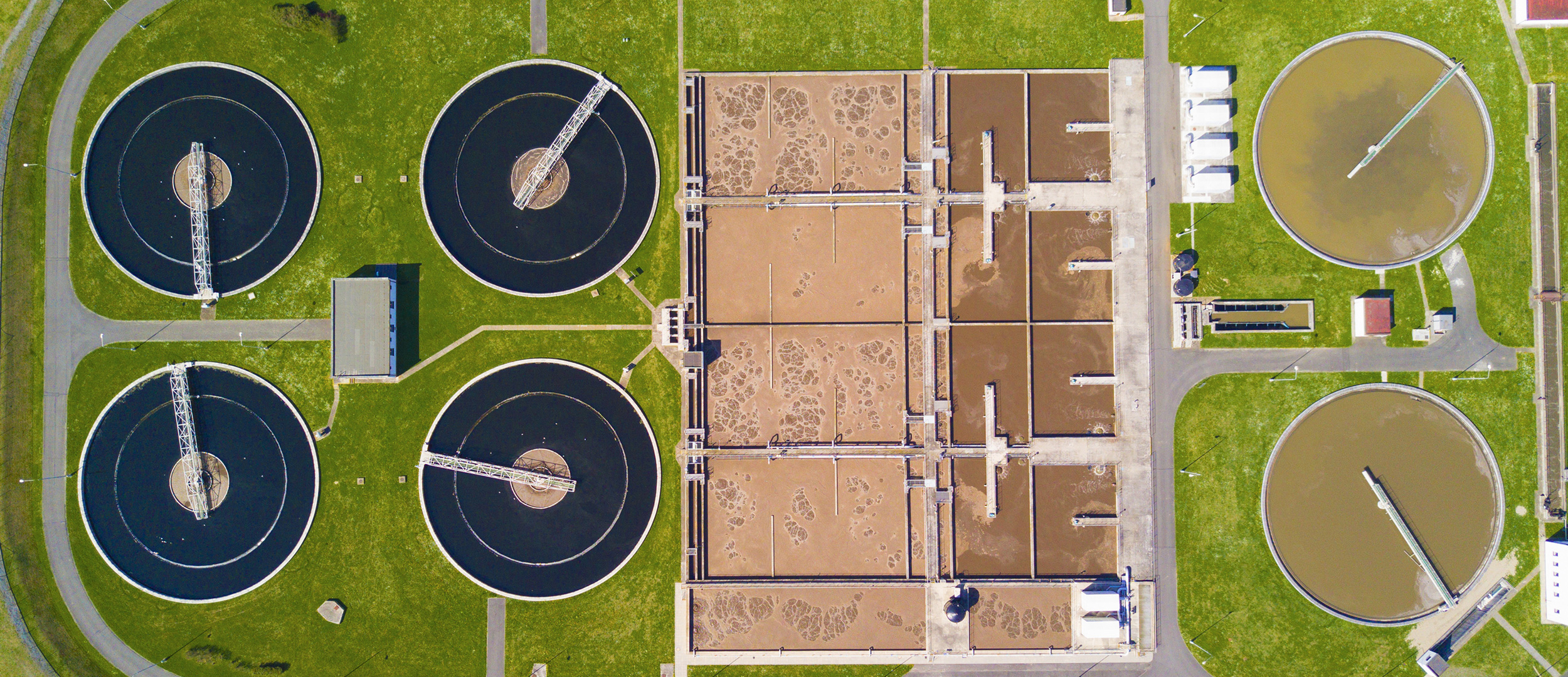

QUALITY IS SUSTAINABLE

Sustainability and ecology are fundamental principles in NILS’ research. We offer a wide range of high-performance, sustainable and biodegradable lubricants that due to their quality, offer improved economy on the quantities used, whilst guaranteeing high machinery efficiency and respect for the environment.